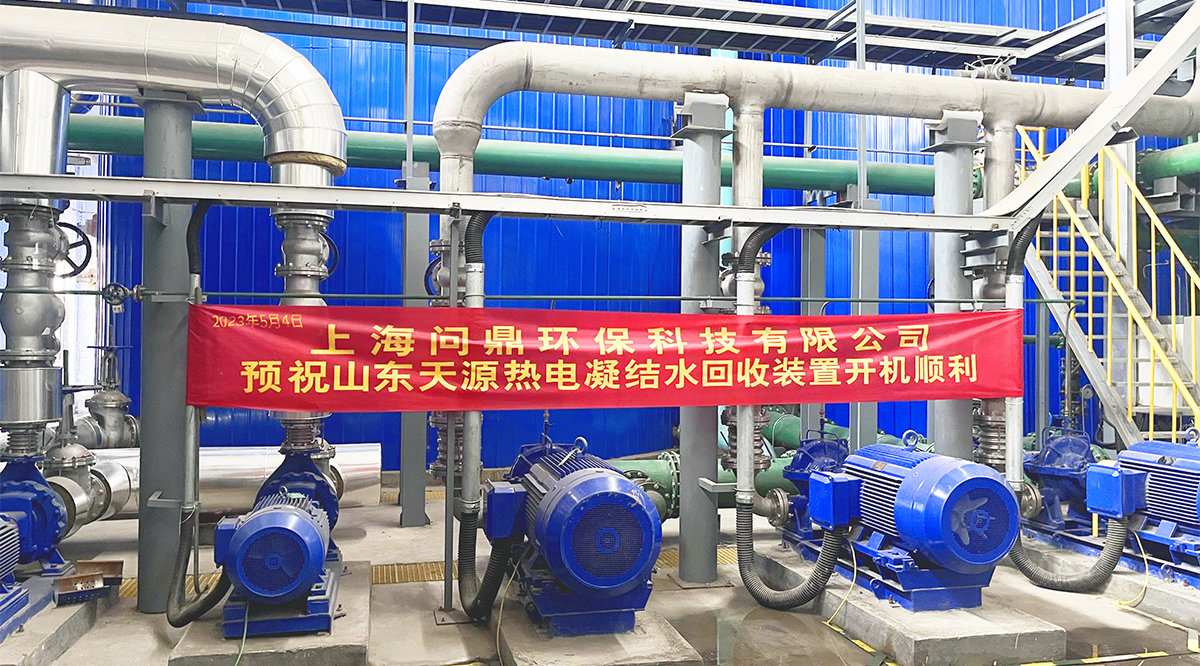

Company news

The 450t/h condensate recovery system of Sinar Mas Shandong Tianyuan Thermal Power Co., Ltd. is located in the turbine room workshop of Tianyuan Thermal Power Plant. The treated water is steam condensate. The designed treated water volume is 450t/h, temperature ≤ 90 ℃, and pressure 0.5Mpa. This project belongs to a renovation project, and the implementation of "carbon peaking and carbon neutrality" has always been the guiding ideology of this project. In terms of technical process routes, full consideration is given to how to reduce greenhouse gas effects and reduce environmental pollution. The technical team actively studies the entire process theory and the technology limit energy consumption model, and through the application of the best applicable commercial technology BACT and integrated innovation in fields such as intelligent management, interface energy efficiency improvement, and deep resource utilization of waste heat and energy, approaches the limit energy efficiency, explores water-saving and energy-saving, and creates economic value. During the project implementation period, it also received full support and active cooperation from the owner. Finally, with the joint efforts of the Wending Environmental Protection Project team and the owner, the system was officially put into use on May 4, 2023. As of now, the system has been stable and reliable in operation, and has created significant economic benefits while achieving full recovery and treatment of condensate. It has reduced self use steam, reduced coal consumption per unit of steam, and achieved low-carbon Green circular economy.

This project is equipped with four 150t/h mixed beds, three for use and one for backup. Fill the anion and cation exchange resin in a 2:1 ratio. The evenly mixed cation resin and anion resin are closely interlaced, and each pair of cation resin and anion resin particles is similar to a set of composite beds. Therefore, the mixed bed can be regarded as an ion exchange device that operates in series with countless sets of composite beds. Since hydrogen ions and hydrogen oxygen ions entering the water after mixed ion exchange immediately generate water molecules with very low Degree of Dissociation, it is rarely possible to form counterions generated during cation or anion exchange, which can make the exchange reaction very thorough.

In addition, the project has also set up four 150t/h fiber filters, three for use and one for backup. One end of the fiber bundle filter material is fixed on a fixed porous plate, and the other end of the filter material is equipped with a self-service adjustment device that can change the fiber density. During operation, the equipment receives water from the lower part and water from the upper part. Under the action of water flow, the self-service fiber density adjustment device drives the fiber filter bed to run upwards, compressing the fiber filter layer. Its stacking density gradually increases along the water flow direction, causing the porosity of the filter layer to gradually decrease along the water flow direction. The corresponding pore diameter and porosity of the filter layer gradually decrease, thus forming a particularly ideal variable pore deep filtration state.

Strict management has been implemented, ensuring safety institutionalization, construction standardization, identification and systematization of materials and equipment, and standardization of process data during on-site construction, ensuring safe construction and achieving dynamic management of the construction site. Strictly control quality, strictly implement various construction standards and specifications, and achieve design specifications for core key equipment/processes.

The project has been running continuously since May 4, 2023, with a stable and reliable system and qualified effluent indicators, creating significant economic benefits and achieving full recovery and treatment of condensed water. According to the design water production capacity of 450t/h, the comprehensive water treatment cost has decreased by 5.1 yuan/t. Based on the current supply capacity of 170-200t/h of desalinated water, the annual comprehensive water production cost has been saved by 7.488-8808 million yuan. Through the installation of this condensate recovery device, the power plant's chemical water treatment system reduces the power consumption per ton of water by 2.22Kwh/t, saves 3.252-3.828 million Kwh of electricity annually, and reduces the annual emission of CO ₂ by 3275.3~3855.4t. The thermal deoxygenation steam reduces by 12.84t/h, the annual consumption of self use steam decreases by 110900 tons, the annual cost savings are 21.96 million, and the annual CO ₂ emissions are reduced by 27647.37 tons. Comprehensively saving electricity and steam, with an annual CO ₂ reduction of 32000 tons.